With the growing demand for space and underground resource exploitation, it is urgent to exploit special power supplies operating under elevated temperature exceeding 100°C.

Rechargeable magnesium batteries (RMBs) have great potential in satisfying this specialized application market due to the high melting point (651 °C) of Mg metal, as well as superior thermostability and lower propensity for dendrite formation of Mg metal anodes. However, conventional Mg electrolytes can only operate at room temperature or bellow, which hinders the development of high-temperature RMBs.

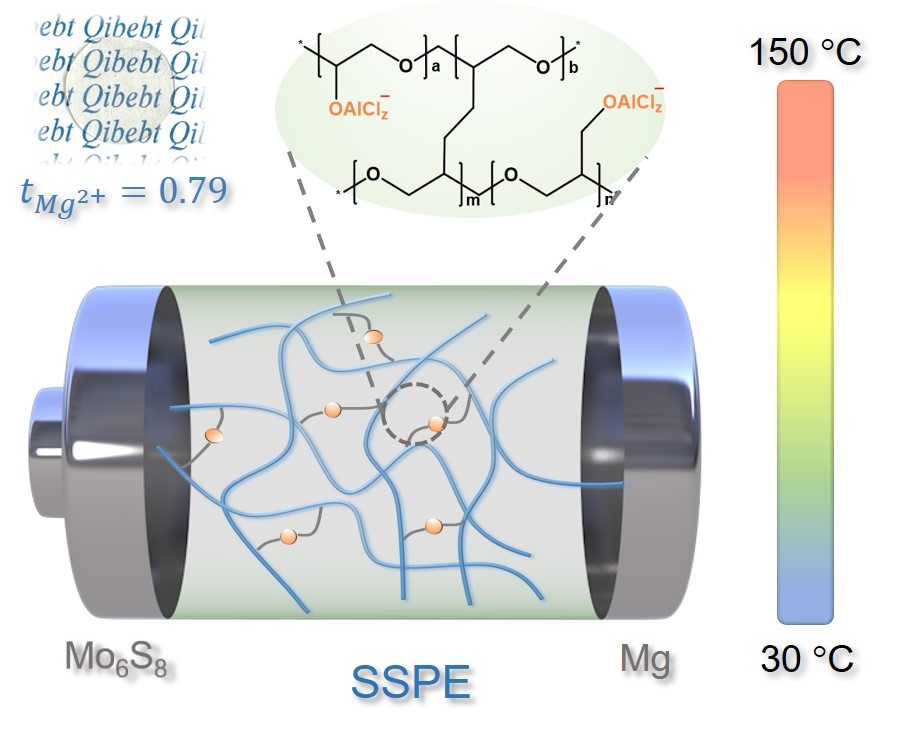

Now, a research team led by researchers from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences (CAS), has developed a robust self-standing single-ion polymer electrolyte (SSPE) for high-safety RMBs at elevated temperature even up to 150 °C.

The study was published on June 29 in Advanced Energy Materials.

This electrolyte exhibits an expanded electrochemical stability window of 4.8 V (vs. Mg2+/Mg), a remarkable Mg2+-ion transference number of 0.79 and a highly reversible Mg plating/stripping performance, outperforming previous reported state-of-the-art RMBs.

It enables Mo6S8//Mg batteries with superior wide-temperature (from room temperature to 150 °C) performance and improves safety merit under abuse conditions due to its high thermal stability and nonflammability features. "Our design concept for self-standing polymer electrolyte provides a promising path to enable high-safety RMBs operating at elevated temperature, which is a significant milestone for boosting the application of RMBs," said by Prof. CUI Guanglei from QIBEBT, corresponding author of the study.

The study was supported by the National Natural Science Foundation of China, Natural Science Foundation of Shandong Province, Strategic Priority Research Program of Chinese Academy of Sciences and Shandong Energy Institute.

Robust self-standing single-ion polymer electrolytes enabling high-safety magnesium batteries at elevated temperature. (Image by GE Xuesong)

(Text by GE Xuesong, Du Aobing)